Christiani Industry Models

Christiani industry models are built from fischertechnik components to represent different processes and applications. All models are stabilised by aluminium profiles and use industry-standard industrial sensors. The open system opens up the possibility of connecting different controllers with 24 volts and sufficient inputs and outputs. Christiani industry models are delivered ready-wired and on a robust pedestal.

What can you do with the Christiani Industry Models?

Christiani industry models are used to teach trainees how to program and commission systems. From simple programming to control loops, from the basics to highly complex processes, a wide range of tasks can be realised with the practice-oriented models – completely risk-free:

- Selection of the appropriate control system

- Wiring the control system to the model

- Programming and testing

- Commissioning of the system/application

- Abstract process thinking

- Troubleshooting

Advantages of the Christiani Industry Models:

- Robust

- Versatile

- Optimum price-performance ratio

- Close to industry

- Directly applicable

- Hands on training without risk of expensive production downtime

- Compatible with all 24 V control systems

- Wide range of models available

- Entire production lines can be built with combination models

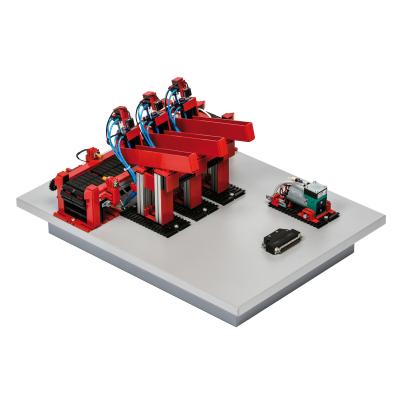

Stand-Alone Models

As the name indicates, the stand-alone industry models from Christiani are closed processes. Here you can choose between ready-to-use bundles with model, control system and the first tasks. Or larger models, such as versions of different process lines, where the planning and commissioning is fully in the hands of the trainees after the control request. Even though the main requirement here is programming, the models must be appropriately wired in advance. They are the perfect tool for learning how to commission industrial processes. In doing so, it is impossible to cause cost-intensive downtimes.

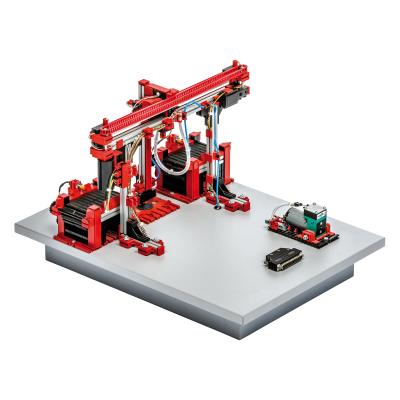

Industry Model Industrial Gate

Sensors:

- 2x One-way light barrier

- 8x Mechanical switch

Actuators:

- 1x Motor with one direction

- 2x Motor with two directions

Requirements for the control:

- 10x Digital input (+read)

- 9x Digital output (+switching)

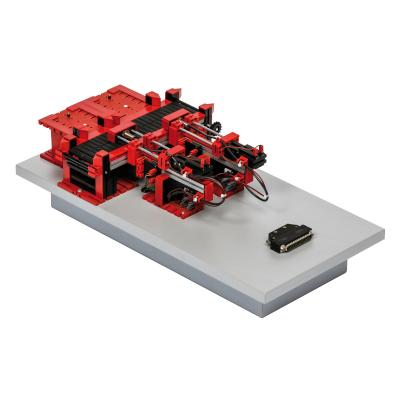

Industry Model Climate Chamber

Sensors:

- 4x Mechanical switch

- 1x Alternator

- 1x Potentiometer

- 1x PT100 temperature sensor

Actuators:

- 1x Motor with one direction

- 2x Motor with two directions

- 1x Heating 40 W (incandescent lamp)

Requirements for the control:

- 3x Analogue input (0 – 10 V)

- 2x Analogue output (0 – 10 V)

- 4x Digital input (+reading)

- 4x Digital output (+switching)

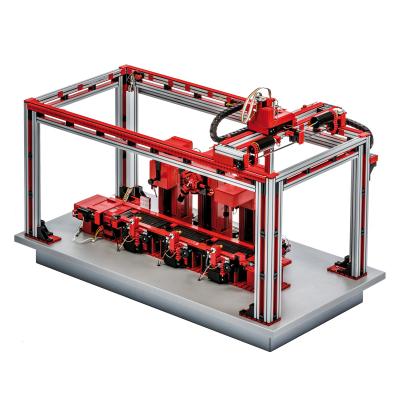

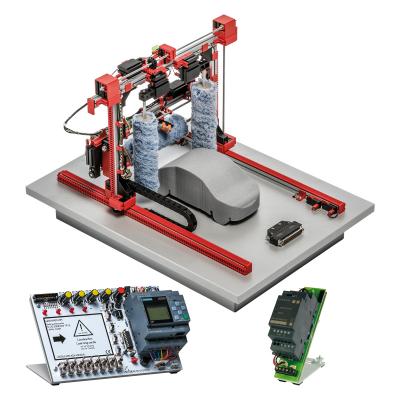

Industry Model Process Line

Sensors:

- 2x One-way light barrier

- 3x Inductive proximity switch

- 20x Mechanical switch

- 2x Incremental encoder

Actuators:

- 7x Motor with one direction

- 8x Motor with two directions

- 1x Electromagnet

Requirements for the control:

- 25x Digital input (+read)

- 6x Counter input

- 24x Digital output (+switching)

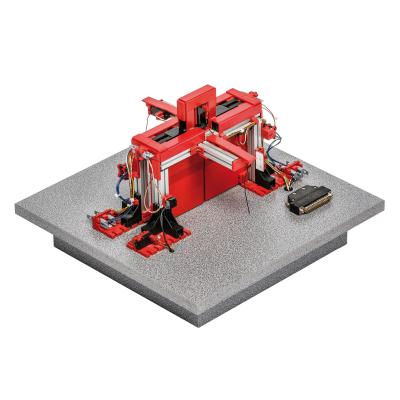

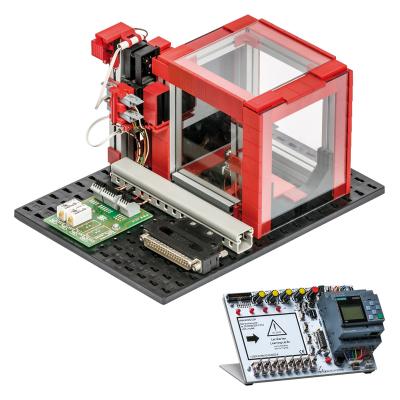

Close-up view of the Industry Model Processing Unit

- Industrial processes in compact design

- Ready for immediate use (Plug & Play)

- The main objective is to learn how to program

- Understand how programmers think

- Industrial sensors are used

- Different functional units in one system 90° swivel table vertical milling machine rail-guide-conveyor belt

- SUB-D connection

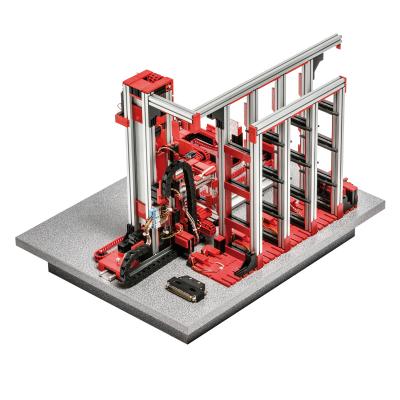

Combinable Model

The combinable models of the Christiani industry models can, as the name indicates, be combined. They represent individual modules that can be combined to form a complex production process. In this way, processes can be simulated as they actually take place in production.

All combinable models are built so that their process control always takes place at the same distance from the base plates. Thus, they can be placed directly next to each other and a transfer of the workpieces is ensured. With the combinable models, the focus is on programming and commissioning. Planning the right control system and the corresponding wiring is also in the hands of the trainees.

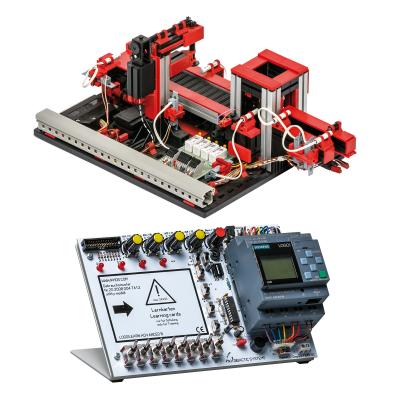

Getting started in PLC programming with the Christiani PLC Starter Kits

All industry models can be operated with common PLCs: Real-life conditions for future professionals. From open-loop/closed-loop control technology to programming, from the basics to highly complex processes, a wide range of tasks can be realised with the practice-oriented models.

- Cost-effective

- From simple logic operations to complex control loops

- Preparation for industrial control systems

- Made in Germany

- Industry-standard look and feel

- Ready for immediate use

- Commissioning & troubleshooting

- Fischertechnik components reinforced with aluminium profiles

- Hands on training without the risk of damaging expensive systems

Do you have any further questions?

We will be happy to advise you on which solution is best suited for your company or educational institution.